PVDF Electrodes

In order to take advantage of the piezoelectric effects in the polymer electrodes need to be securely attached to the PVDF to take advantage of the the piezoelectric effects. Traditionally these electrodes are made of metal. Measurement Specialties, Inc. sells PVDF with screen printed silver, copper and carbon electrodes. The metal electrodes are rigid hindering the performance of the PVDF. Using the conductive polymer PEDOT/PSS the flexibility is increase which greatly improves the performance of devices created with PVDF, such asbimorphs and actuators. The other reason we prefer the polymer electrodes is because we can apply them here at MSU.

The challenge comes in attaching the PEDOT to the PVDF. PVDF has a hydrophobic surface and PEDOT is mostly water so it beads up on the surface of the PVDF and doesn't stick well. Another problem that has been encountered is that PEDOT shrinks when is dries which causes problems with keeping the thin sheets of PVDF flat. Also if the PEDOT is applied in large amounts at a time there are problems with it becoming brittle and cracking.

So far there are 3 methods which have been used to apply PEDOT to PVDF.

The first method uses ion-assisted-reaction (IAR) to treat the surface of the PVDF and then the PEDOT is screen printed on. C. S. Lee, J. Y. Kim, D. E. Lee, J. Joo, B. G. Wagh, S. Han, Y. W. Beag and S. K. Koh, Flexible and transparent organic film speaker by using highly conducting PEDOT/PSS as electrode, Synthetic Metals 139, pp. 457-461, 2003.

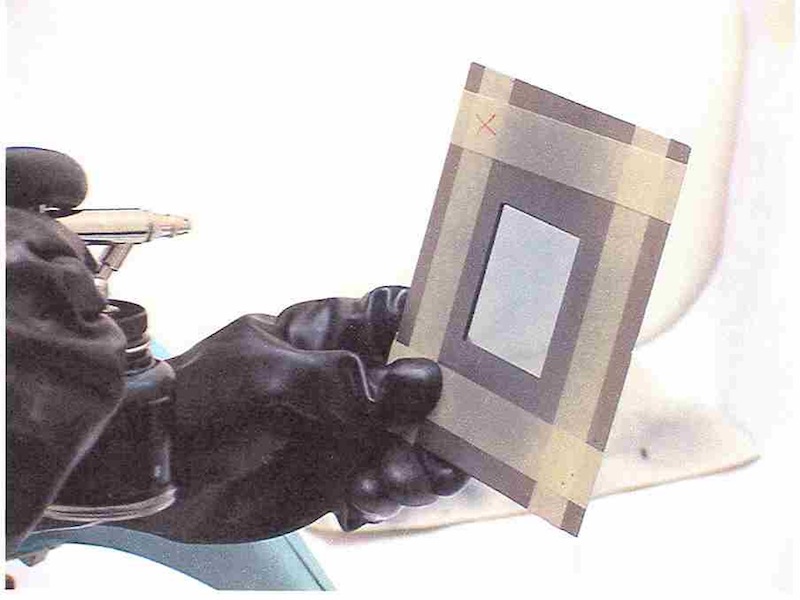

The second method was done here at MSU by Jil Hallenberg. Her technique involves plasma etching the surface of the PVDF and then airbrushing the PEDOT on thin coats. A primmer consisting of PEDOT and some other chemicals is also require to be used of the PVDF prior to applying the rest of the PEDOT electrode. Details can by found in Jil Hallenberg's ME masters thesis at MSU.

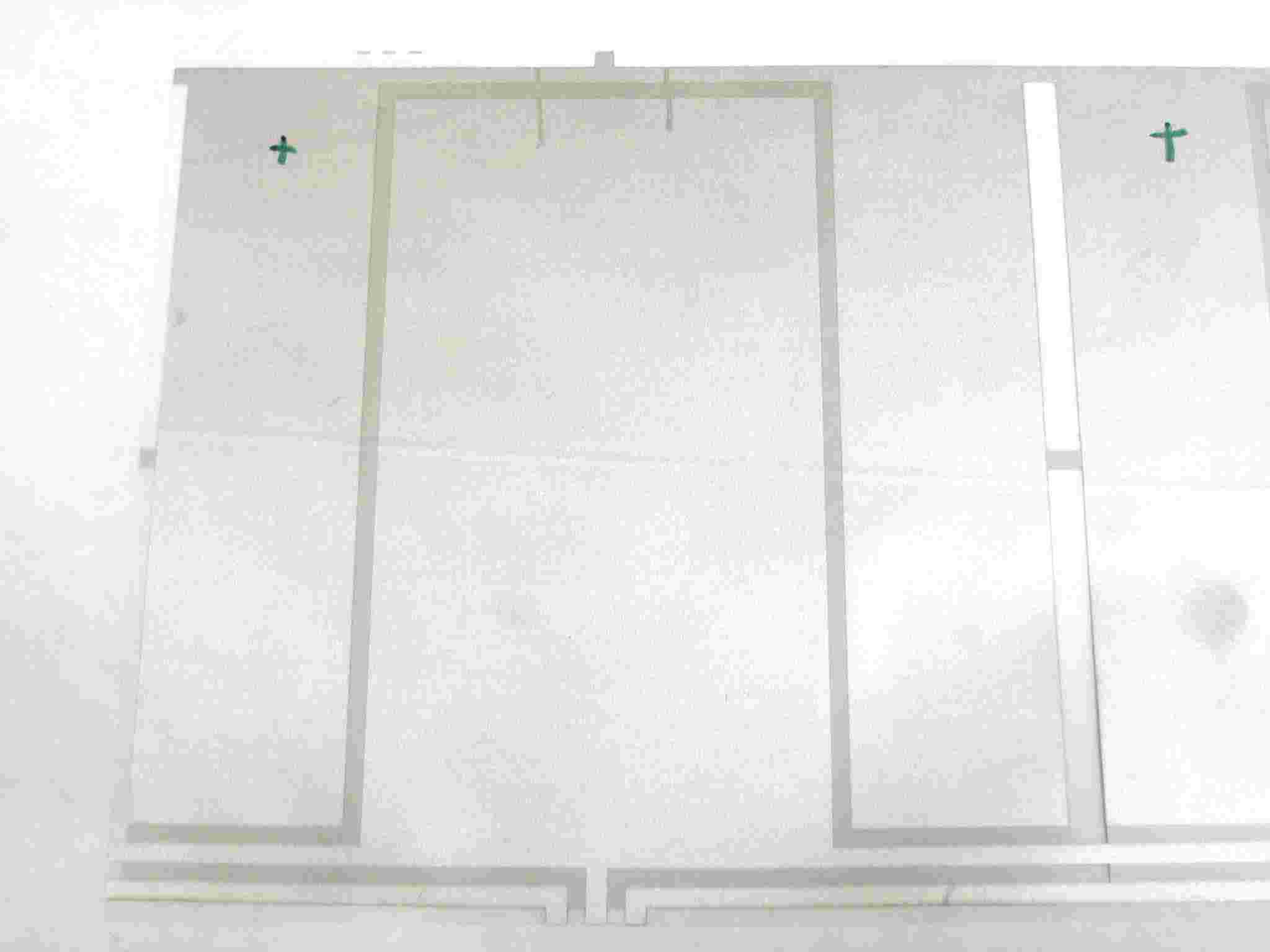

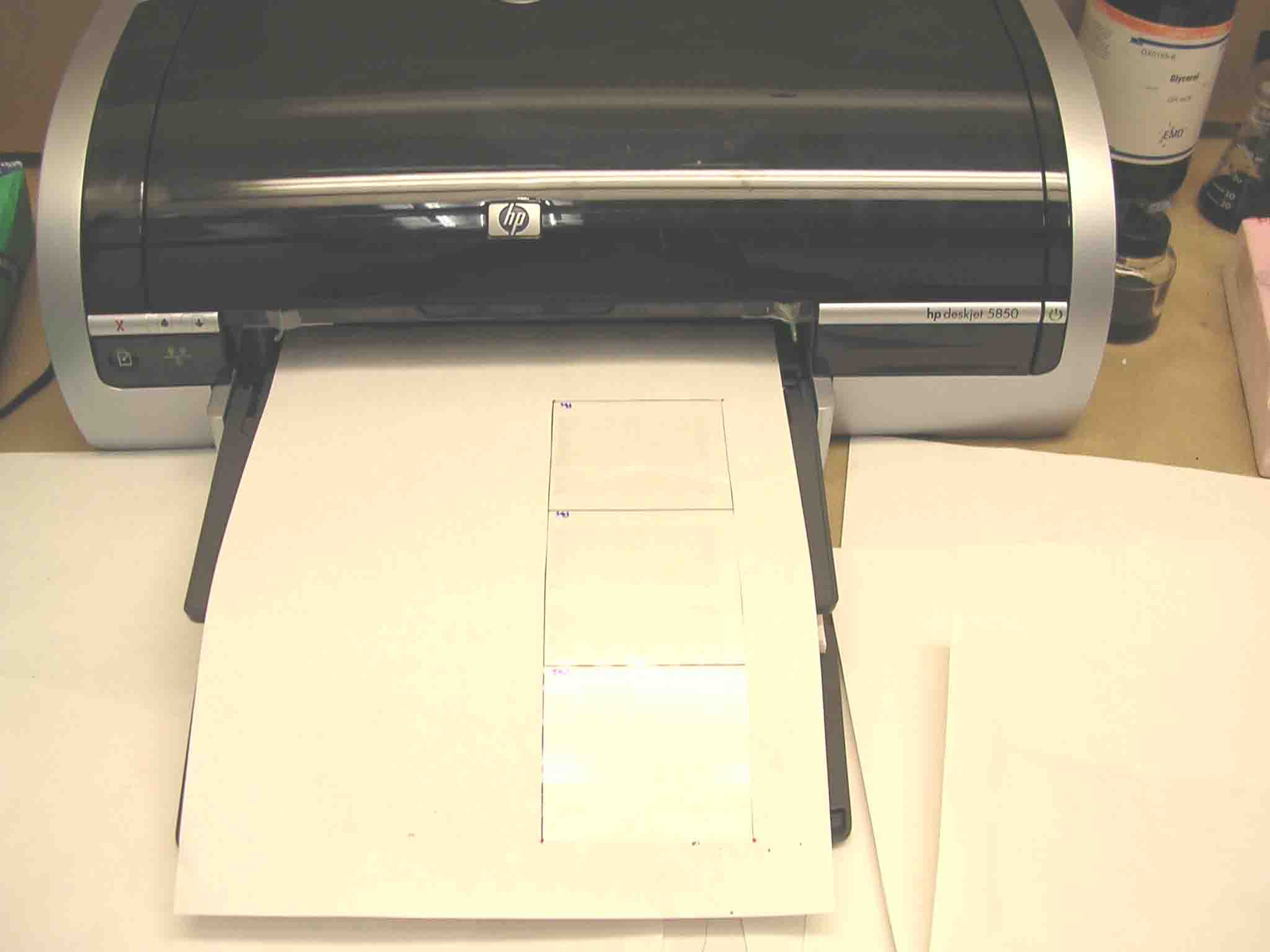

The third method was accomplished by Joe Polasik here at MSU. This is also the method that we currently use for electroding PVDF. It uses an inkjet printer to apply the PEDOT in very small amounts improving the adherence to the PVDF. The inkjet method is very beneficial because of the ease of use and the consistency of the results. Any electrode pattern desired can be created and the adherence is excellent without prior treated to the surface of the PVDF. The output volume of the PEDOT is also easily adjusted as seen in the first picture below.

Updated: March 14, 2013 14:24